Cloisonne' Enamel...What the heck is it?!?

...A myriad of colors to choose from in enamel.

Prep work; Sketches have been done, A design decided upon, Fine Silver [.999] has been flashed [heated close to melting point to achieve high silver sparkle that will shine through layers of enamel]. Silver is domed.

A thin coat of clear enamel is applied to front and back side of piece. NOW fine silver[.999] wires are carefully placed to form design and channels to hold enamel in place. Counter enamel is put on backside of piece. This balances out tension of enamel, keeping the piece from fracturing.

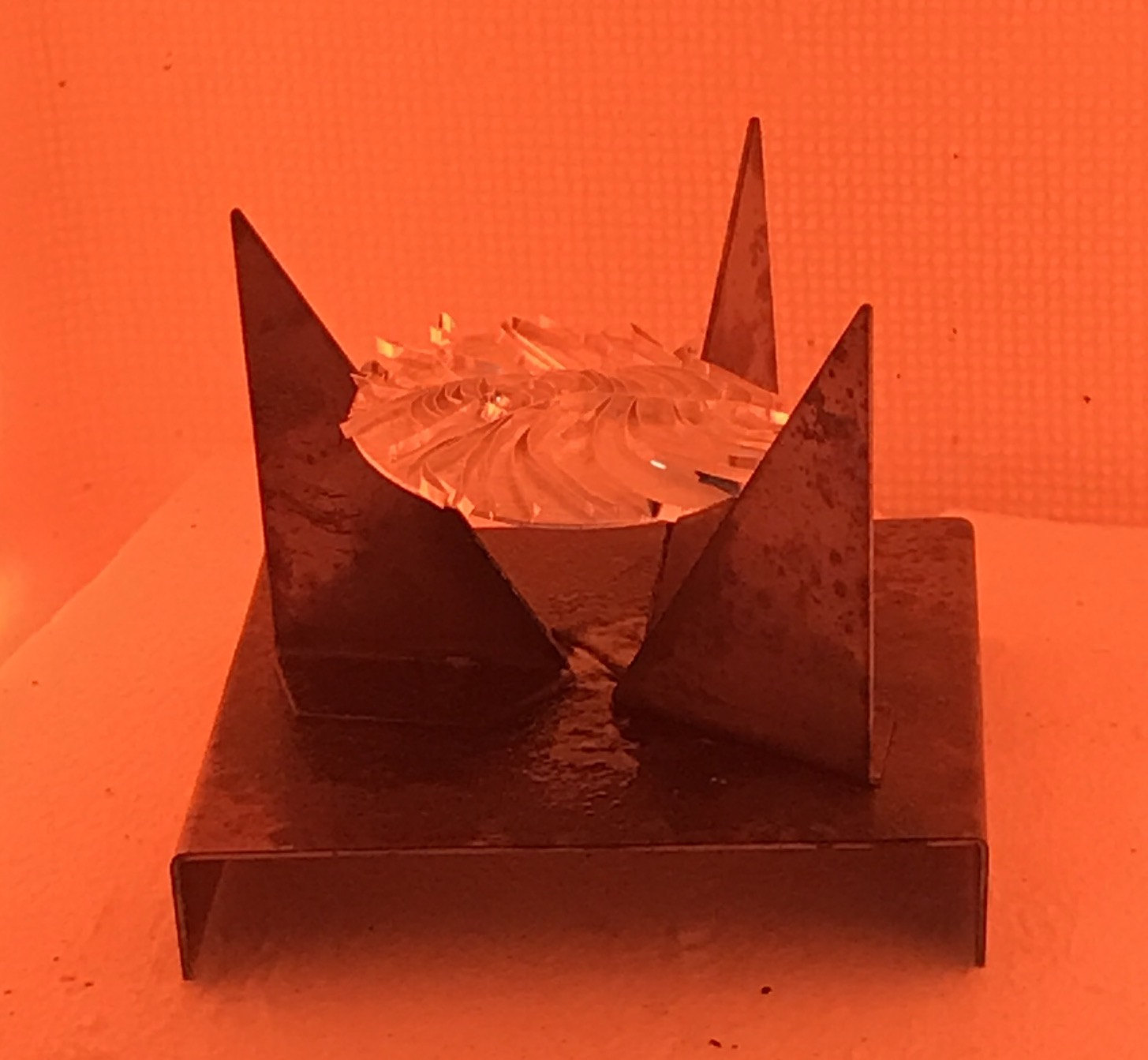

All wires are set into place and piece is fired in kiln [1450F] to adhere them to the thin coat of enamel on surface.

...All wires in place on top of layer of clear enamel, ready for the first firing to adhere wires to enamel and surface of fine silver.

........Red hot [1450F] piece of work being removed from kiln. It's allowed to cool then successive layers of color are applied.

........Thin layers of enamel are carefully brushed into place. Enamel is carefully dried then fired after every application.

.....more layers added and fired.

...Inside the kiln. Some colors mature at lower or higher temperatures. Work must be fired on a stilt to make sure the glass surface does not stick to anything when the enamel melts. It is fired to a desirable 1450 degrees F.

Layers of colored enamel are applied until enamel is close to the top of the wires. Once all color is in place, thin coats of transparent enamel are layered over surface. A piece may be fired up to 20 times to achieve color and layering desired for completed piece.

THEN sanding of the surface begins. Alundum stones and water are used, sanding with finer and finer grit until the surface is smooth and even.

...an Alendum stone. Next I will sand with wet-n-dry sandpaper, starting with a 400 grit and successively finer papers.

Once the sanding is complete, the piece is washed to remove any fine residue then fired again to “Fire Polish” the surface, leaving it smooth and glossy.

The piece is then fitted for a handmade Sterling Silver setting and followed through to completion.

![ All wires are set into place and piece is fired in kiln [1450F] to adhere them to the thin coat of enamel on surface. ](https://images.squarespace-cdn.com/content/v1/5a5678987131a52a7064acf1/1516138091602-2PMQQ3VFU6L4CJ8E1BHZ/isbi_fullxfull.1267109563_tkx0yz7z.jpg)

![........Red hot [1450F] piece of work being removed from kiln. It's allowed to cool then successive layers of color are applied.](https://images.squarespace-cdn.com/content/v1/5a5678987131a52a7064acf1/1516138231180-9BY4Z4CIVGNQ3C32O2NM/isbi_fullxfull.1267111177_oasg3efn.jpg)